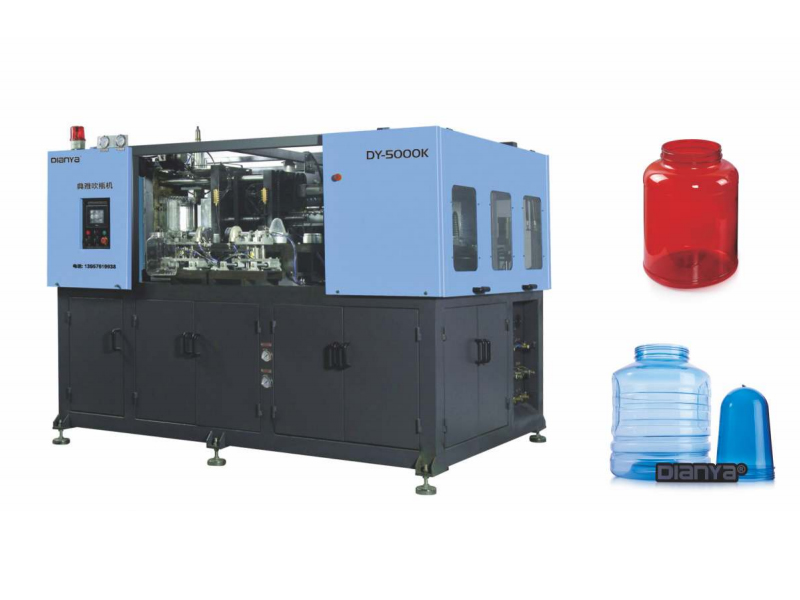

A PET material bottle making machine is one of the most […]

A PET material bottle making machine is one of the most practical and efficient ways to make your own bottles. PET stands for polyethylene terephthalate, which is a popular plastic that can be found in most plastic bottle brands. With PET, it's easier than ever before to make your own custom-made bottles, and save a lot of money on store-bought plastic bottles.

There are many different types of PET bottles, including water, juice, milk, juice boxes, shaving cream, baby food, confectionary, shaving cream and more. PET bottles can also be used for medical purposes. In fact, they're very popular in the dental field. These bottles are made with a special type of heat, which makes them soft and durable, and which allows the liquid inside to expand and contract to fit the airtight seal.

These types of bottles are generally made using high quality materials. One of the best types of PET is PETT, which is made from polyethylene terephthalate. Because it's very durable, PET is resistant to bacteria and other harmful chemicals. Another type of PET bottle is called PETw, which is created from a combination of PET and glass. These types of bottles are considered less toxic and also have the same qualities as glass.

Your best bet is to get a PET material bottle making machine that will allow you to choose the material that you want and be able to customize the design. If you're unsure about what kind of material you want, ask for help or do some research online. You should also know exactly how much money you want to spend on your machine. Most of the time, there's a machine available for just a few hundred dollars.

The only thing you need to consider before you buy a plastic bottle making machine is what you want to make. There are several different types of designs that you can choose from, and you can even get one that makes labels. Once you know what you want to make, you can look into how the material is created.

While some machines are more complicated than others, some of them are easier to use. If you can handle the parts and have a little knowledge of electronics, you may even be able to do the design yourself. if you don't know anything about electronics or plastics. It's actually fairly easy to design your own machine, and then order your own supplies and equipment.

You can design your own machine, and then order your materials. Once your materials arrive at your place, they can be disassembled and put together, giving you a bottle that is totally unique. You can then design the label or use the same design as your own.

You can even design your own personalized bottle so that every person who buys it knows who created it. And because you know exactly how the bottle was made, you can create many more bottles that the rest of your friends will like as well.

You can make one bottle with the same design or choose an original design for each batch of bottles that you create. You can also have the machine print out labels so that each person can see how much they've spent.

Most of these machines are pretty inexpensive, which means that you can start your own business right away. The best part about the machine is that it lets you make more than one bottle with the same design and label. This means that you'll have an endless supply of bottles to sell.

Once you've started your small business, you can always add more machines and create more batches of bottles and make your business bigger and more profitable. With your machine, you can even expand your inventory, increasing your profit.

When it comes to choosing the right material, you should make sure that it is durable enough for the job, especially when it comes to the chemicals you use. And that the machines are easy to use. Some machines are difficult to operate, but most are quite straightforward to operate.