Automatic blow molding machine for plastic bottles is t […]

Automatic blow molding machine for plastic bottles is the most advanced tool for high-volume plastic bottle filling. It can fill a variety of bottles and should be considered a valuable part of any professional beverage bottling machine. This machine has been developed by APRO, a French company that has made a lot of advancement in the sphere of beverage machines. In fact, all of their products are outstanding and have gained a lot of popularity. Bottle fills using this machine have gained great acceptance throughout the world.

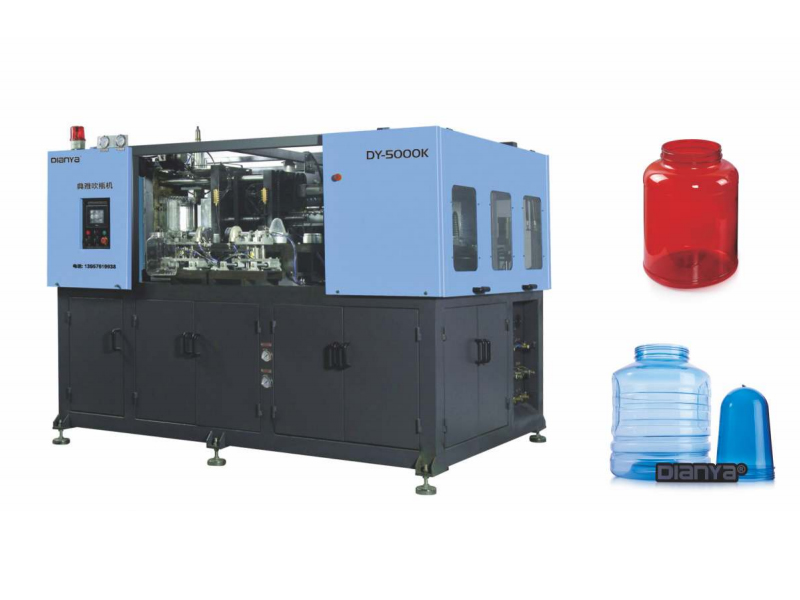

The Automatic Blow Molding Machine for beverage production line is basically a fully automated machine. The machine is designed to generate high pressures that are required for the manufacture of small round bottles. The machine has the capacity to produce up to nine hundred cups at a time from two liters of PET bottles. This is one of the biggest advantages of using this product for beverage production line. Apart from being utilized for beverage production, it can also be used for pet bottle filling. As compared to manual bottle filling methods, the production line operated by Automatic Blow Molding Machines is more reliable and efficient.

This blow molding machine for PET plastic bottles is very simple to operate. It has the ability to apply the right amount of pressure depending upon the type of bottle that needs to be manufactured. The machine applies the right type of heat that ensures proper melting of the plastic when the pressurized air is released during the PET bottle molding process. A skilled operator can easily manufacture round the same PET plastic product over again without having to touch the bottle.

This machine has the potential to increase productivity in any industrial manufacturing as well as automotive shop. This can easily be used in automotive shops to manufacture plastic products such as hoses, gaskets, exhaust systems, fuel tanks, radiators, carburetors, seals, etc. If the equipment used for blow molding is run manually, it can take a lot of time. It will also consume too much energy and money. However, if you use Automatic Blow Molding Machines, you can save on both the time and money that is required to manufacture high quality automotive and plastic products.

With this automatic pet bottle blow molding machine, it is possible to manufacture a full range of high-quality parts and accessories that are available on the market today. When selecting the best Automatic Blow Molding Machine, it is important to check the product details to find out if the product meets the required standards. Some of the features that need to be checked include the material that has been used for the plastic material and the vacuum pressure, the feed rate, the feed volume, the auto shut-off temperature, the product detail and the packaging capacity.

Automatic blow molding machines are ideal for producing plastic bottles with the desired shape and size. For instance, it can be used to manufacture polycarbonate or clear polycarbonate bottles. These types of plastic bottles are very strong and can be used in any place. Furthermore, Automatic Blow Molding Machines can also be used to manufacture high-density polyethylene or PVC bottles. This kind of product can be used for bottles that are extremely long-lasting.

The best blow molding machine is one that is reliable and efficient. Therefore, it is important to check the warranty and return policy before purchasing Automatic Blow Molding Machines. Moreover, a reliable automatic machine will have good warranty coverage and will be able to offer support even after the warranty period has expired. In addition, the Automatic Blow Molding Machine will require minimal maintenance once it has been purchased. Some of the simple maintenance activities such as cleaning and oiling will be sufficient to ensure that the machine runs smoothly for many years.

Another potential problem that could arise from using automatic blow molding machine is the danger of chemicals being released during the process. For example, when plastic is placed under pressure, some of the chemicals released are flammable. Therefore, it is important to store the Automatic Blow Molding Machines properly. In addition, the universal and the parallel axis machines should be kept separate. In case of both of these machines getting in the way of each other, the automatic machine would experience problems and the chances of causing damage to the casting surface would increase.